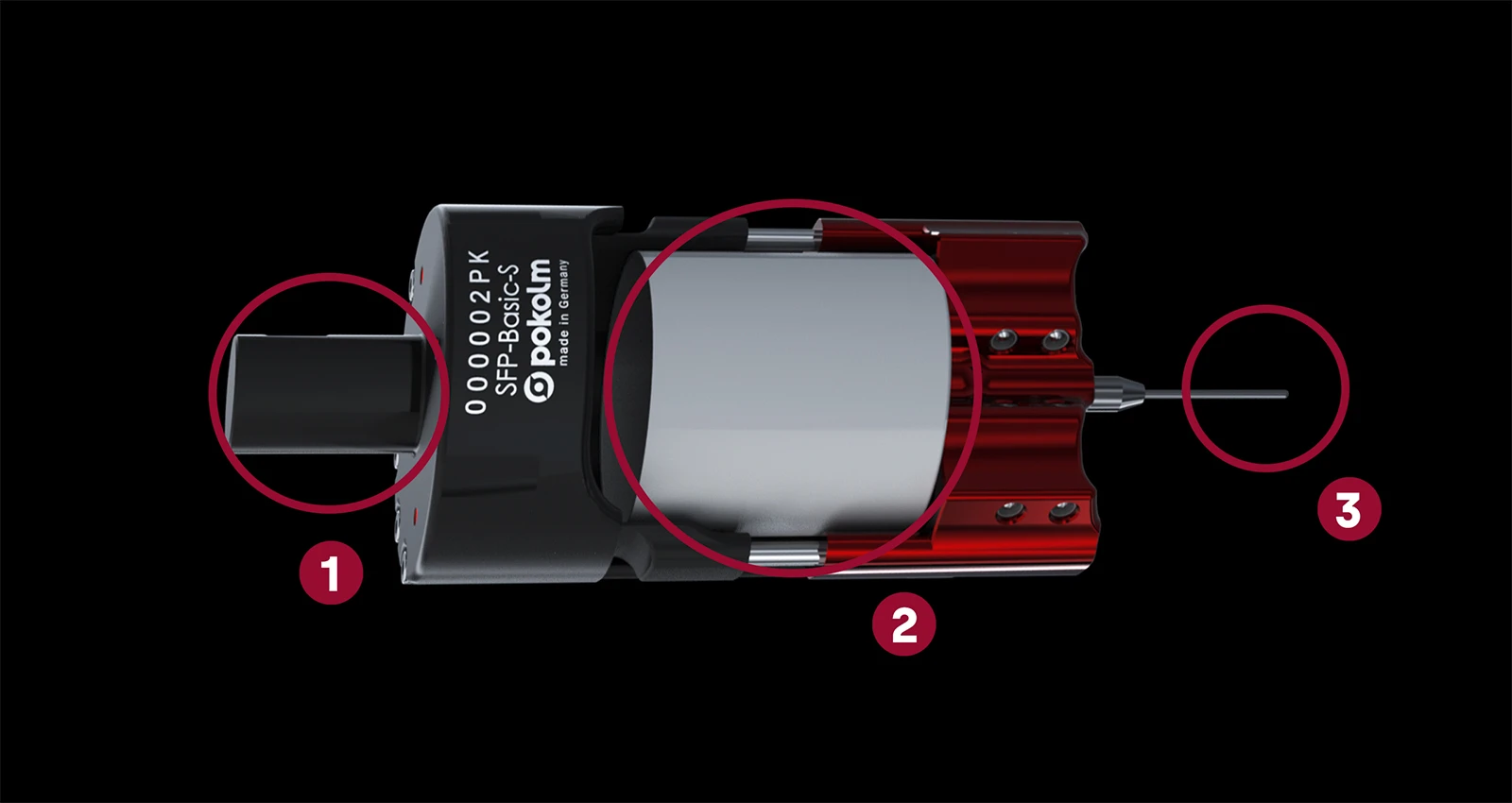

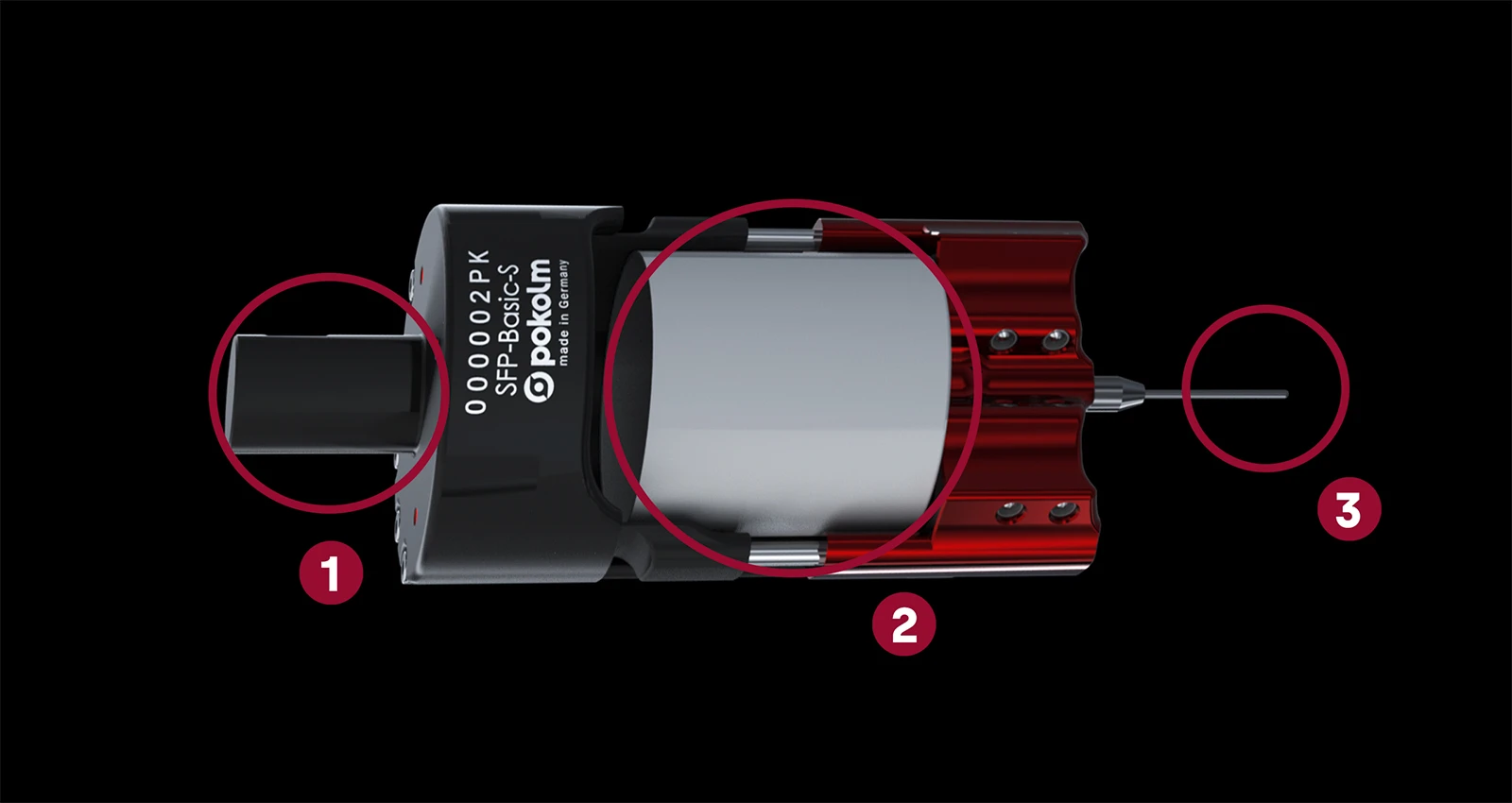

- can be used in standard chucks

- quick filling thanks to replaceable cartridges

- optimized, even lubricant delivery

Spotfix allows lubricant to be applied precisely and accurately to core holes. In the production process, the contactless lubrication system enables threads to be manufactured automatically. Spotfix can be customized.

When threads are manufactured, an automated process increases safety and reduces costs. However, the lubricating effect of the machine's own cooling lubricant is often insufficient for machining threads in high-alloy steels, for example. If thread milling is not an alternative, the program must be stopped to manually grease the core hole.

Spotfix supports automation. Clamped into a tool holder, the lubrication system applies cutting grease precisely and accurately to the core hole without interrupting the ongoing manufacturing process. Insufficient lubrication and over-lubrication are avoided, as is unnecessary contamination by the cooling lubricant.

Regardless of the spindle interface, Spotfix can be used in any standard chuck and provides reliable assistance in the unmanned, fully automatic production of threads. Spotfix is also suitable for lubrication during thread forming.

Are you looking for a suitable solution for your challenge?