With the Uniworx® product family, Pokolm is pursuing a clear strategy: universality, flexibility, and efficiency in fine machining and demanding milling tasks. Discover the strengths of Uniworx® and Uniworx® PLUS, as well as their similarities.

With the Uniworx® product family, Pokolm is pursuing a clear strategy: universality, flexibility, and efficiency in fine machining and demanding milling tasks. Discover the strengths of Uniworx® and Uniworx® PLUS, as well as their similarities.

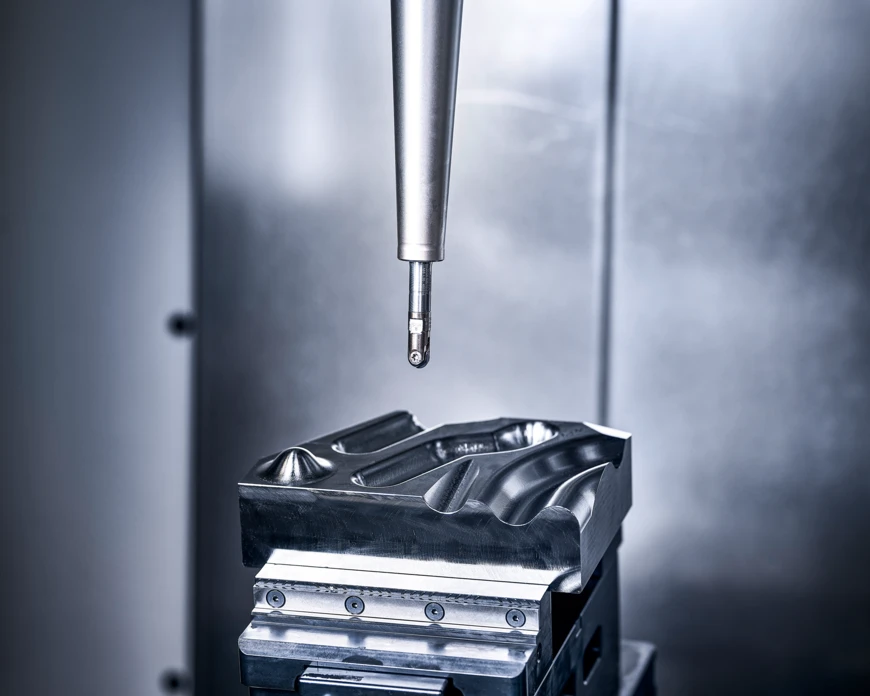

Uniworx® tooling systems are known as universal milling cutters for fine machining. The milling tools with ball or torus inserts are ideal for finishing steel, cast iron, and hard materials.

Uniworx® tools are available in various diameters from 8 to 20 mm. All indexable insert milling cutters are available as screw-in or shank milling cutters and with the Duoplug® connection developed by Pokolm for maximum concentricity and rigidity. An internal coolant supply ensures high process reliability and reliable removal of disruptive chips

Uniworx® PLUS is an indexable insert milling cutter with one-piece cutting inserts, developed for a wide range of roughing, finishing, and residual material machining applications.

With just one tool body, Uniworx® PLUS milling tools enable the use of corner radius and high feed inserts. All Uniworx® PLUS tools are available as screw-in and shank milling cutters and with the Duoplug® connection system developed by Pokolm for maximum concentricity and rigidity. For optimum process reliability, all Uniworx® PLUS milling systems feature a unique internal coolant supply with a fan-shaped opening through the indexable insert. The perfectly coordinated coolant channels ensure maximum acceleration of the coolant.

The Uniworx® product family from Pokolm stands for universal solutions in machining: whether fine machining or high feed rates, free-form surfaces or precise corners—with Uniworx® and Uniworx® PLUS, you can cover an impressively wide range of milling operations. Uniworx® offers a compelling tool concept for companies that value flexibility, low inventory, and efficient, stable processes.